Why and How to Ensure Fluid Clarity: A Guide to Killing Fluid Turbidity Checks

The need to maintain a transparent

killing fluid in oil and gas well control operations cannot be overstated. For

operational safety, efficiency, and effectiveness, it's crucial to be able to

accurately measure the turbidity of killing fluids, which is a measure for

cloudiness or clarity. This piece will elaborate on the importance behind

killing fluid turbidity checks as well as the techniques used to perform this

essential task.

As per this approach killing fluid turbidity

Well turbidity – is a measure of the

cloudiness or haziness of a fluid due to suspended particles. These include solids,

contaminants and other materials. On the other hand, when it comes to well

control operations, there are clarity requirements for the killing fluid, i.e.,

the fluid in which the flow of formation fluids is stopped and controlled,

since the killing fluid should be completely devoid of particles causing

suspension. Excessive turbidity can limit visibility, effect well control, and

be a hazard to personnel and equipment.

Killing fluids are pumped into a

well to increase pressure on formation to halt the flow of formation fluids.

For this purpose, these fluids must be of high quality to ensure effective and

safe functioning of the systems. High turbidity of killing fluid can signify

excessive solids or contaminants that prevent it from adequately displacing

formation fluids. This, in turn, can increase the frequency of well control events

- including blowouts, fluid migrations or equipment failures.

It is important to take care of

killing fluid turbidity.

Operational Safety

Clear killing fluids are an integral

part of operational safety. Personnel involved in well control operations

require clear visibility of fluid behavior to accurately assess the downhole

conditions. High turbidity can also make it hard to see into the wellbore,

hindering operators from seeing how a fluid behaves or if anything is going

wrong.

Unclarity can cause operational

errors, decision-making failure, and slow reactivity when it comes to dangerous

situations. Turbidity that is too high could also make it challenging for

personnel to notice and remediate well control problems early, such as a

formation fluid influx, and that could cause catastrophic outcomes including

blowouts.

Effectiveness of Well Control

Essentially, killing fluids are used

to suppress and retain control of a wellbore by pushing formation fluids away

and sealing off unwanted influxes of gas or oil. The clarity of the liquid

causing the kill bad directly affects its effectiveness. The use of clear

brines ensures better placement and displacement of formation fluids, which is

critical for well control.

If the turbidity levels are too

high, the efficiency of fluid displacement may diminish. Particulate matter in

the fluid, for instance, may impede flow or lower the overall efficacy of the

fluid in forcing formation fluids back into the wellbore. It is imperative to

address turbidity as it can cause such delays, incomplete well control, and

loss of well integrity.

Equipment Performance

The abrasive particles contained in

turbid killing fluids significantly threaten surface equipment, including pumps,

valves, flowlines, and monitoring instruments. These particles can cause

equipment wear, increase maintenance costs, and lead to operational downtime.

If you do not address this, then the incessant flow of cloudy fluids may cause

critical pieces of equipment to fail prematurely, culminating in expensive

repairs and replacement parts.

Routine checks will help operators

avoiding issues while allowing them to degrade performance through the clarity

of the fluid, which can help them sustain operations, extending cost-efficient

machinery life and also preventing costly breakdowns.

Methods to Check Killing Fluid Turbidity

Different techniques can be used to

evaluate killing fluid turbidity, each providing distinct benefits and

applicability in various operating conditions. Reliable turbidity readings are

crucial for complying with fluid clarity limits, and a selected approach should

be according the operation requirements.

Visual Inspection

Visual inspection is one of the

simplest and most economical turbidity monitoring techniques. Watch the killing

fluid for signs of cloudiness or sedimentation, or suspended particles.

Operators can observe the fluid through a transparent container or examine the

flow from a surface storage tank.

Even though visual inspection is

fast and cheap, it is very subjective. Different personnel may interpret the

clarity of the fluid differently and minor turbidity fluctuations may go

unnoticed. Visual inspection is therefore generally regarded as a less accurate

method than other, more sophisticated, approaches.

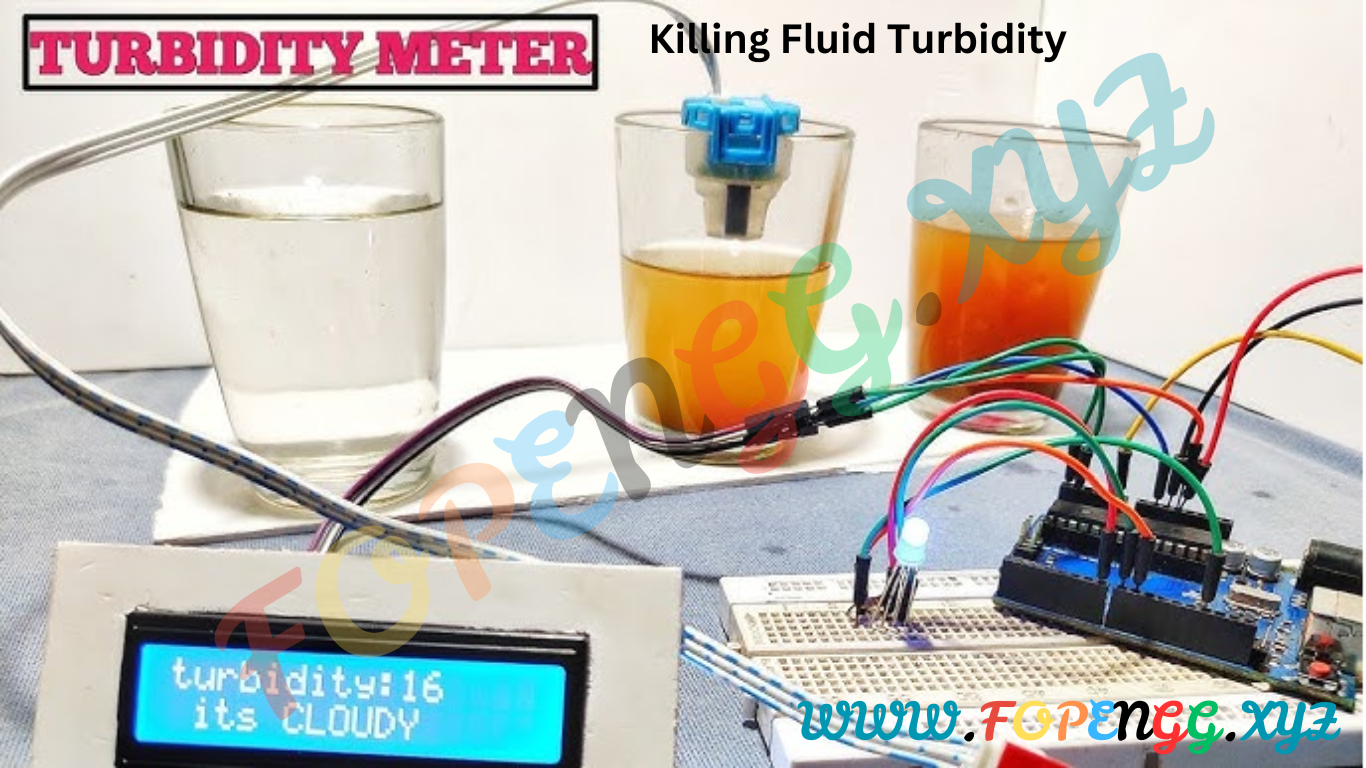

Turbidity Meters

Fluid turbidity is measured using

instruments called turbidity meters (also termed turbidimeters or

nephelometers). These executes a technique of light disarranging or ingestion

for estimating the measure of suspended particles in the fluid. The device

shines light through the sample and monitors the extent to which that light is

scattered or absorbed by the particles suspended in the fluid.

Rather than relying on visual

inspection, turbidity meters give more accurate, objective, and reproducible

measurements. They are especially useful for continuous monitoring and for

operations where precision is paramount. Turbidity Meters (Portable or Inline):

A handheld turbidity meter is most suitable as it gives quick and immediate

results to ascertain turbidity levels, while other inline monitoring systems

can be integrated into the fluid circulation system (recirculating waters in

aquaculture).

Laboratory Analysis

Another highly accurate approach for

measuring turbidity of killing fluids is through laboratory analysis. The

wellbore fluids are extracted and analyzed thoroughly in the laboratory.

Methods like centrifugation, filtration, and microscopy are used to isolate and

count the particles in suspension.

Laboratory analysis as an analytical

technique for its high reliability while imparting chemical components details

of the killing fluid. Yet, it has some limitations with respect to time taken

to process the samples and need for extra resources. This kind may not be appropriate

for real-time decision-making in rapid operations.

Online Monitoring Systems

During well control operations,

killing fluids turbidity is monitored in real time using online monitoring

systems. These systems usually include sensors or probes placed at various

points along the fluid circulation path within the wellbore to continuously

monitor turbidity during fluid traversal. State-of-the-art systems use

turbidity monitoring units, which strategically installed within the pipelines,

or continuous monitoring devices that relay data in real-time to the operators

so they can assess any changes in turbidity and intervene if necessary.

A major benefit of real-time

analysis and intervention is that continuous data capture with online

monitoring systems is possible. Advanced systems like these are even more

effective in high-stakes operations that need immediate response to mitigate

risk and preserve well control.

How to Check Killing Fluid Turbidity – Best Practices

Best practices must be followed to

ensure reliable and accurate turbidity measurements. The below best practices

are required to maintain the fluid in the desired field and achieve successful

well control operations.

Calibration

For the turbidity meters and online

monitoring systems, the instruments need to be calibrated regularly, otherwise

the measured value can vary from the true turbidity. Calibration keeps

instruments within their specified tolerance ranges and maintains data quality

over time. Improperly calibrated instruments might give skewed turbidity

readings leading to false conclusions causing wrong actions.

Sampling Protocol

To obtain accurate laboratory

analysis of turbidity, proper sampling protocols must be followed to ensure that

samples collected reflect the condition of the fluid as a whole. This covers

factors such as sampling at sites around the circulation, ensuring the sample

is uncontaminated and the sample not changed in any way prior to testing.

Threshold Limits

The establishment of predetermined

threshold limits for acceptable turbidity levels constitutes an essential

component of operational planning. They serve as indicators for well control

decisions and thresholds for intervening. The thresholds can be set by the

operator based on operational experience, industry standards, and the well-specific

conditions.

Documentation

Turbidity measurements must be well

documented for the well control operation record. Such documentation must

describe the methods and instruments used in the process and the results

achieved. Accurate and thorough documentation allow for tracking fluid clarity

trends over time and allow for audits and performance analysis.

Conclusion: Protecting Lucidity for

Successful Control of Well

These are just a few outlines of

well control operations and the necessity of inertia when it comes to checking

killing fluid turbidity in operations in the oil and gas industry. Operators

can improve operational safety, maximize the effectiveness of well control, and

safeguard equipment integrity by eliminating this ambiguity associated with

killing fluids. The verification of fluid clarity by using a combination of

visual inspection, turbidity meters, laboratory analysis, and online monitoring

system allows practitioners to maintain the accuracy of the evaluation and take

timely necessary corrective actions.

Turbidity as killing fluids is very

important. But with complex, increasingly high-risk oil and gas operations

today, maintaining fluid clarity is essential to enable safe, efficient and

reliable well control operations. Clarity in killing fluids is an investment in

a future of operational excellence, safety, and long-term success in the

industry.

killing fluid turbidity, turbidity measurement, well control operations, oil and gas industry, turbidity meters, killing fluid clarity, well control safety, online monitoring systems, operational safety, turbidity analysis, fluid circulation system

.png)

0 Comments