Scrapers in the Oil and Gas Industry:

Introduction

In the complex operations of the oil and gas sector, with pipelines covering hundreds of kilometers and machinery operating under extreme conditions, scrapers become an essential part. These tools specifically designed to clean and maintain pipelines are an essential part of ensuring the integrity and efficiency of fluid transportation systems. This article explains what scrapers are, what they do, their use, and the different types used in oil and gas.

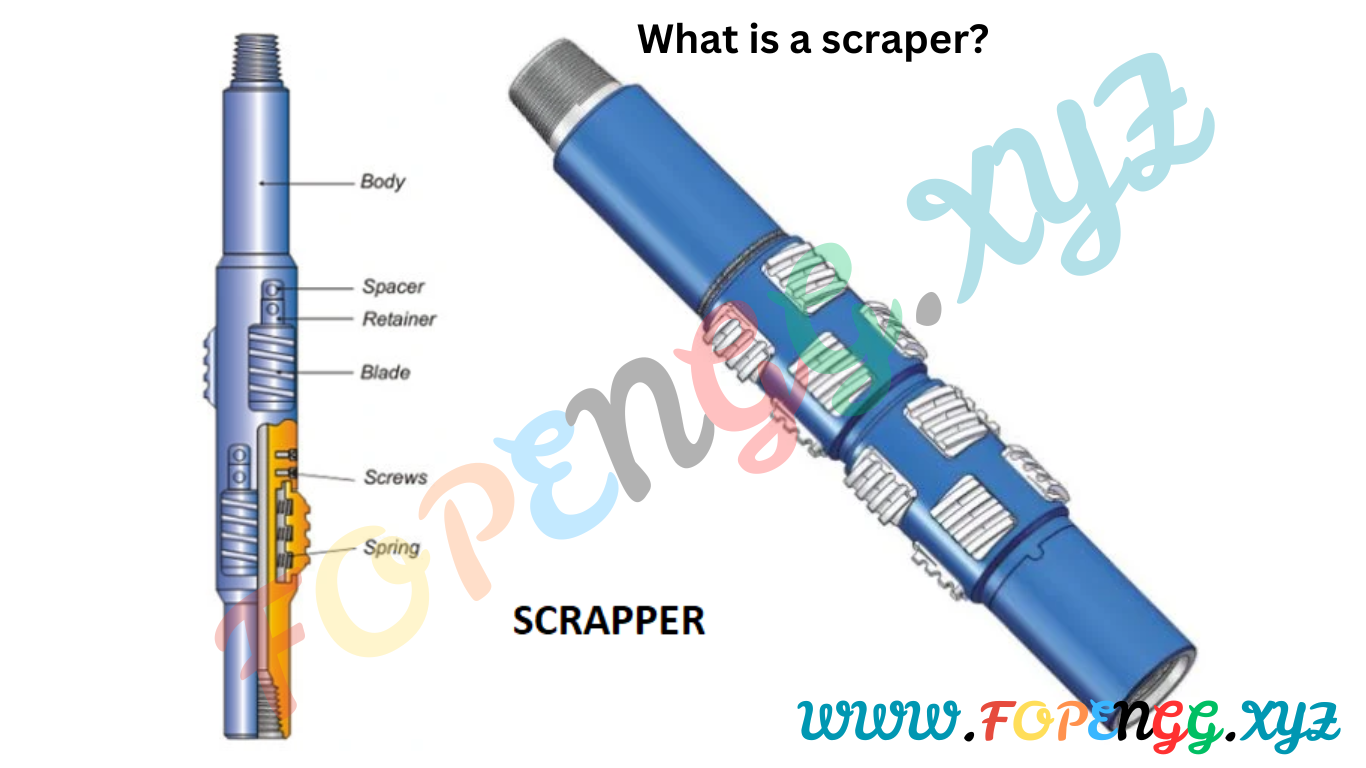

Scrapers: The Essential Pipeline Maintenance Tool

Scrapers are equipment that are meant for cleaning and servicing the internal edges of pipelines as they come into contact with deposits like debris, scale, wax, liquids, etc. over a period of time. While specific geometrical variations are generally known as scraper types, the main function is related to the streamlining or unimpeded movement of the fluids, which enhances pipeline performance, reduces pressure drop, and helps avoid blocks.

Scraper usages in the Oil and Gas Industry

1. Cleaning and Debris Removal

✔Scrapers successfully cleans out built up debris, scale, wax, and additional contaminants from pipeline inner wall and restores them to optimal operational.

✔Scrapers pile up and clogs are removed to create smooth movement of crude oil, natural gas, and other hydrocarbons, and to *Redirect flow to minimize pressure drop in the pipelines for Energy efficient transportation of resources.

2. Inspection and Maintenance

✔Along with cleaning, scrapers can also be fitted with sensors, cameras or inspection tools to determine the condition of pipelines and detect any potential integrity issues.

✔In this way, scrapers also conduct regular inspections during cleaning operations which can help identify any mass defects, corrosion, or irregularities in the pipeline walls allowing for timely maintenance and repair work.

Different Types of Scrapers in Oil and Gas Industry

✔Scrapers vary in types, designed for individual pipeline sizes, configurations, and cleaning needs. Selection of scraper type is based on the pipeline diameter and operating conditions and the nature of deposits to be removed.

1. Mechanical Scrapers

✔Mechanical scrapers, which have blades, brushes, or scraping elements attached to the end, physically dislocate debris and deposits from the walls of pipelines.

✔These scrapers apply mechanical force to loosen and remove impurities from the scrapper, providing comprehensive pipe cleaning.

✔Enable JavaScript-Mechanical scrapers are best suited for pipelines with moderate to heavy buildup and effectively remove stubborn deposits or hard to remove deposits like scale or wax.

2. Foam Scrapers

✔Foam scrapers use soft flexible foam pads or brushes to scrub and clean the inside pipe surface without scratching it.

✔These scrapers are perfect for cleaning light to medium deposits, such as dirt, rust, and light scale, while reducing the chance of abrasion or surface damage.

✔Foam scrapers are mainly used in pipelines with sensitive linings or coatings that need to be cleaned gently to keep their integrity.

3. Scrapers for Gauging and Inspection

✔Used as a final smart solution before switching from doubt to certainty, gauging and inspection scrapers measure the pipeline dimensions, integrity and cleanliness with the help of sensors, cameras or measurement devices.

✔These devices give essential information on pipeline status, particularly inner diameter, wall thickness, and the existence of defects or abrasions

✔A critical component of pipeline integrity management, which allows operators to detect potential problems and to prioritize maintenance work.

4. Smart Scrapers

✔These are also called as advanced or intelligent scrapers which involve sophisticated sensors, data logging capabilities, and real-time monitoring systems.

✔Industry Context - Approaching the Industry 4.0: Smart scrapers in pipeline applications, Collecting data: Smart scrapers can monitor and analyze data on pipeline conditions, fluid properties, and operational parameters providing diagnostic insights into performance and computations.

✔They can provide enhanced functionalities like automatic operation, remote inspection, and predictive maintenance, which improves the efficiency and reliability of cleansing and maintenance process in pipeline cleaning.

Scrapers as a Tool for Pipeline Integrity Management

✔By virtue of the role that corrosion, leaks and failures play, pipeline integrity is a paramount concern in the oil and gas industry. Tools like scrapers provide a vital role in pipeline integrity management (PIM) by:

✔Preventing corrosion by eliminating *moisture and contaminates.

✔Avoiding chokepoints that can cause pressure surges and operational failures

For example: – Identifying potential weaknesses before they become expensive failures.

✔Increasing the lifespan and reliability of pipeline infrastructure, lowering maintenance costs and cutting environmental risks.

Scraper Technologies: Challenges and Future Trends

1. Operational Challenges

✔Although they have their benefits, scrapers also come with operational challenges, including:

✔Pipelines curves and restrictions, which could prevent scrapers from passing.

✔Deposit adhesion, which can complicate cleaning in older or very active pipelines.

✔Equipment wear and tear: how often do companies need to conduct maintenance and replacement?

2. New technologies & innovations

✔Intelligent scrapers and the duel hygiene system are some of the Key highlights of pipeline cleaning technology. Some future trends include:

✔Automated and robotic scrapers that can negotiate complex pipeline geometries.

✔AI-driven data analysis for predictive maintenance and real-time condition monitoring

✔Environmentally friendly scraper solutions which are less harmful for cleaning houses.

✔The Right Scraper: Efficiency and Integrity at Its Best

Doubtless, scrapers contribute significantly to the oil and gas industry by navigating pipelines and enabling their continued cleaning, inspection, and maintenance. Such scrapers provide the unimpeded flow of fluids and optimize pipeline performance while eliminating operational risks by scraping debris, scale, wax and other contaminants.

There are different types of scrapers; so the operator has the advantage of choosing the right tool for the right application of the scraper, promo-fueled by the application of mechanical scrappers for heavy-duty cleaning, foam scrappers for light surface cleaning or (for advanced monitoring and analysis) smart scrappers. A commitment to safety, efficiency and environmental stewardship in the fluid transportation operation process is upheld in the industry by emphasizing pipeline cleanliness and integrity.

In this way, the oil and gas industry can benefit from pipeline longevity, operational efficiency and reduced environmental risk for years to come, by keeping pace with innovative scraper technologies.

.png)

.png)

0 Comments