Fluid Dynamics of Oil and Gas: Static & Dynamic Losses

Static & Dynamic Losses: The

Backstory In Oil & Gaz Industry Fluid Dynamics The oil and gas industry is

complex, and so is fluid dynamics, breaking it down further to static and

dynamic losses is crucial. Losses due to friction, resistance, and changes in

velocity are critical to the design and optimization of fluid flow systems.

Whether estimating losses from pipelines to wellbores and surface equipment,

accurately computing these losses is crucial to ensuring that operations can

run smoothly and performance is reliable. Join me as we explore the why and how

of calculating static and dynamic losses in oil and gas systems.

Static and Dynamic Losses: An Introduction

Fluid dynamics in the oil and gas

industry: Oil, gas, and water must travel through various pipes, wellbores, and

equipment in the oil and gas production process, making fluid dynamics an

essential factor in maximizing operational performance throughout the industry.

Fluid flow systems have their drawbacks, however. A major part to this

challenge is analyzing and calculating the losses incurred while fluid flows.

Losses can be broadly classified into two types: static and dynamic losses.

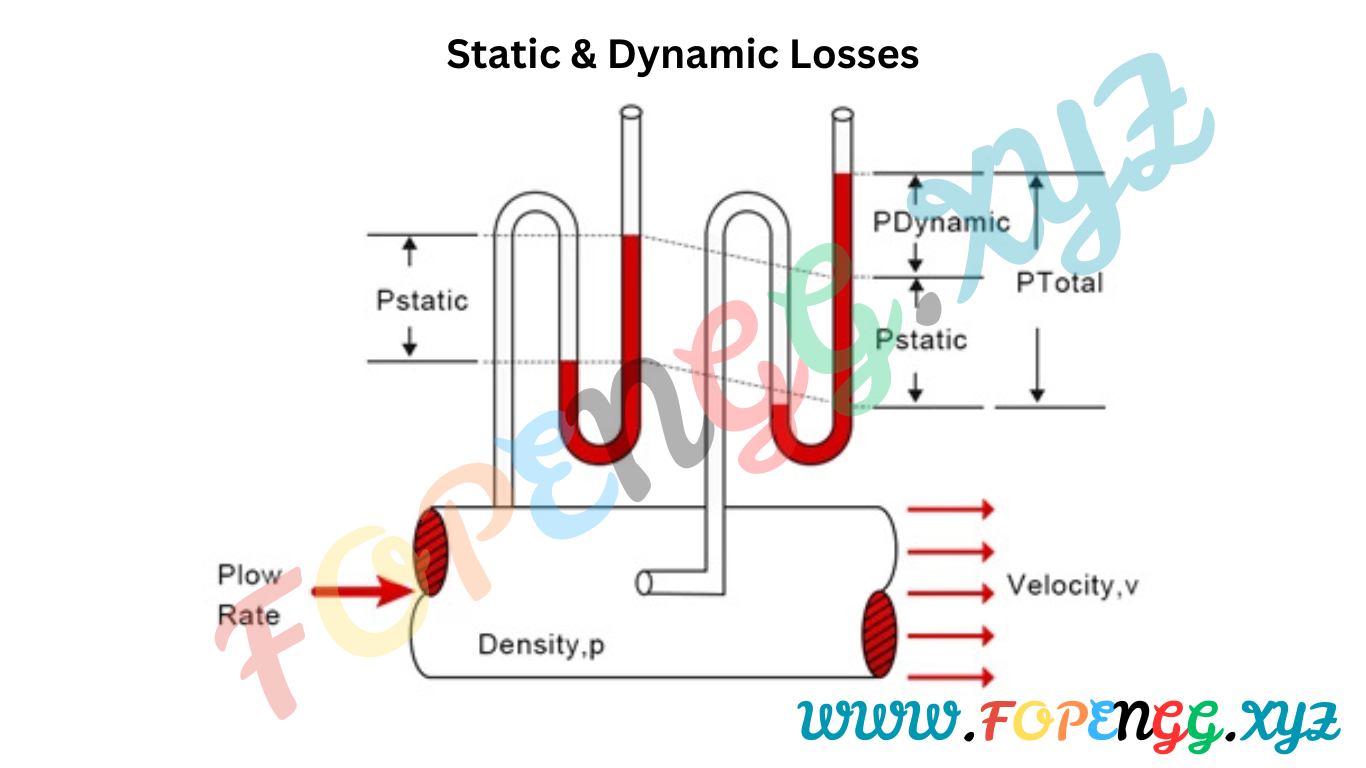

Static losses are due to resistive

and friction losses in the stationary elements of the system. Static losses are

due to the existence of a pressure difference (usually, static pressure) on the

two ends of the component, whereas dynamic losses are related to the change in

the velocity or direction of fluid flow. These losses influence the pressure,

flow rate and energy consumption of the system. Mastery of loss types in electric

machines is essential for system design, energy optimization and maximum

equipment benefit.

Friction and Resistance: Static Losses in Stationary Parts

Static losses—these are the pressure

losses due to wall friction and resistance of the stationary parts of a flow

over a pipe and valve system, funneling system, and overall restrictions.

Losses — these are important to understand system behavior, and their influence

reaches out to process efficiency, cycle sizing, and system performance tuning.

Importance of Static Losses:

Increased General Efficiency: More

static losses mean less fluid moving through the system and therefore less

pressure which means the transfers required are less than desired. The demand for

more energy in the system can also come from the system flow rate and pressure

distribution, which can be impacted by these losses.

Equipment sizing– To select the

right equipment, static losses should be known accurately. This involves

selecting the right pipe diameter, pumps and compressors for smooth and

low-pressure drop fluid passage.

Note: Static losses are part of the

system loss related to pressure loss, when these losses are calculated, it

helps to indicate the points that cause inefficiency in the system; therefore

engineers can take corrective measures, by changing the diameter of the pipe or

changing flow conditions.

Methods of Calculating Static Losses:

Darcy Equation The

Fundamental Approach for Static Losses The Darcy equation describes

relationships between the head loss in a fluid flow system to the flow rate of

fluid, the diameter of the pipes, the length of the pipes, and the fluid

properties. This equation also includes the friction factor, which accounts

for the roughness of the pipe and flow conditions, and is an important parameter

in this relationship.

So the basic equation can be charged to obtain the following basic derivation in fluid dynamics:

ΔP = f × LD × ρv 22 \ Delta

P = f \ times \ frac {L} {D} \ times \ frac {\rho v^2} {2}

Where:

✔ΔP\Delta P stands for pressure drop,

✔ff is the friction factor,

✔LL is the length of the pipe,

✔D - D is the pipe diameter.

✔where ρ\rho is the fluid density,

and

✔vv is the flow velocity.

Static Loss: Static losses, in

addition to the frictional, include the minor losses for fittings, valves,

bends, expansions, and contractions. These losses can be calculated based on

empirical data, and there are tables that give loss coefficients of different

components, which in turn are included in the overall losses of the system.

Dynamic Losses: Understanding Fluid Velocity and Acceleration Changes

Dynamic losses are pressure drops

due to changes in fluid velocity, flow direction, or elevation. These losses

are typically related to abrupt changes in the flow pattern of the system, like

bends, tees or transitions in pipe diameters. They are a key contributor to

energy management, enhancing the flow control and minimizing the power demand.

Importance of Dynamic Losses:

Energy Management: Dynamic losses

directly effect the energy consumption of a fluid flow system. Those losses

have an impact on the system pressure variations and can generate inefficient operation.

Dynamic losses, if fictionally managed, can greatly lower energy loss.

Fluid System Design: With proper

insight into how dynamic losses occur, engineers can optimize the design of fluid

systems. For example, these might include modification of the systems for flow

control or even the arrangement of the pipes and minimizing unwarranted changes

in the direction of the flow for smoother flow of the fluid and decrease in the

loss of energy.

Dynamic Losses Calculation Methods:

Bernoulli’s Equation — Bernoulli’s

equation relates the velocity, pressure, and height in a moving fluid. In

addition to changes in velocity or elevation, dynamic loss can also be

quantified by engineers who specialize in these aspects. This equation can be written

as:

P + (12)(ρ)(v2) + (ρ)(g)(h) =

constant P + (1/2)(ρ)(v^2) + (ρ)(g)(h) = constant

Where:

✔PP is the pressure,

✔ρ\rho is the fluid density,

✔vv is the fluid velocity,

✔gg is called the gravitational constant,

and

✔hh is the elevation.

Momentum : The momentum is derived

from newton's second law of motion is used by engineers to calculate dynamic

losses in systems where either flow direction or velocity is near zero. This

might be especially beneficial for systems that feature fast gas expansion or

compression, e.g. flow through control valves, or sudden pipe area changes.

Data: Processing Complexity with Responsiveness

Determining static and dynamic

losses is quite a difficult thing. Methodologically, it involves system

analysis, data collection, calculation and optimization.

System Analysis:

Identify Components: First step is

to Identify all the components in the system that contribute to static and

dynamic losses. Anything from pipes, valves and fittings to elevation changes

and flow restrictions.

Assess the flow conditions in the

system. This will involve familiarity with the fluid and fluid properties, and

how the system works.

Data Collection:

Fluid properties: Get data like

density, viscosity and flow rate of the fluid. These attributes are crucial for

accurately accounting for losses.

Gather details on pipe dimensions

(diameter and length), elevations, valve coefficients, bend angles, and any

other characteristics specific to the components.

Calculation:

Use Established Methods: Use the

proper equations such as Darcy-Weisbeck or Bernoulli’s to compute static and

dynamic losses Make sure all aspects are considered whether small losses,

changes in flow direction or flow velocity.

This should yield Iterative

Calculations: Fluid dynamics calculations will usually need tubular comments to

model real-world differences. Employ computational tools or software to

simulate the system's behavior and pinpoint areas where enhancements can be

made.

Aggregate losses and optimization:

Calculate Total Head Loss: Add the

static and dynamic losses for each component to find the total pressure drop,

or head loss, along the whole flow path.

Optimize: Study the computed losses to

pinpoint bottlenecks or inefficiencies. Optimizing pipe diameters, pump sizes

or circulation patterns to reduce energy losses is part of that.

By minimizing losses and optimizing

system performance, engineers can make sure the system is functioning both as

efficiently and reliably as it can over time.

Optimized Efficiency: A Game of Precision

Note that the losses add to various

(two) segments of pipes and come under static and dynamic losses; Calculation

of these will significantly help in designing, working on, and optimizing

pipeline fluid motion processes for oil and gas systems, in guaranteeing

maximum performance. These losses are more than academic; they impact system

efficiency, operational costs, and energy consumption. Utilizing standardized

mathematical formulas like the Darcy-Weisbeck equation and Bernoulli’s principle,

engineers can solve any quirks that fluid dynamics might add to their systems

and make sure they function properly.

With a systematically planned loss analysis approach — data gathering up to optimization — the oil and gas industry will keep improving fluid flow operations, leading to greater operational efficiency, sustainability, and safety. Not only do accurate calculations help to optimize system performance, but they also help to achieve less energy consumption, lower costs as well as protecting the operational reliability of equipment. Fluid dynamics in oil and gas systems is an essential skill for engineers as the need for resource optimization becomes ever more pressing in our globalized world.

.png)

.png)

.jpg)

.png)

.png)

.png)

0 Comments